WATERJET REPAIR & CNC MACHINE REPAIR

REPAIR

If your waterjet or CNC machine is down, limping along, or simply not cutting precision parts we can repair your issues. Call today to see if we can get onsite on the same day or even connect remotely via TeamViewer to get you back up and running as fast as possible.

REMOTE DIAGNOSTIC

We offer remote connection to help diagnose and resolve your issues quickly.Click here to download TeamViewer - (http://www.teamviewer.com/)

BALLBAR TESTING

If your waterjet or CNC machine is not cutting accurately, have one of our highly trained field service engineers perform a ballbar on your waterjet or CNC machine. After the test, we will know exactly what is needed to get your waterjet or CNC machine back to cutting accurately.

PREVENTATIVE MAINTENANCE

Many companies are doing this because of the significant cost savings from their waterjets or CNC machines being down when they can’t afford to be. And also finding and resolving issues before they happen. We can put together a preventative maintenance plan whether it be annually, quarterly, or even monthly.

INSTALLATION OR RELOCATION

Do you need your waterjet or CNC machine installed or relocated? Don’t hesitate to have one of our highly trained engineers help you get up and running in a timely manner. We will stay until you are cutting precision parts.

EVALUATION OR INSPECTION

Are you looking to buy a used waterjet or CNC machine? Protect your investment by having one of our trained engineers inspect the waterjet or CNC machine before purchasing. Or are you looking for an evaluation on your waterjet or CNC machine? Have one of our factory trained engineers perform a hands on evaluation with a detailed inspection report.

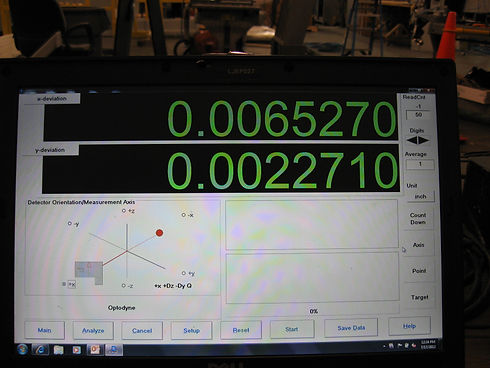

XD CALIBRATION

We recalibrate your Flow waterjet 5 axis XD head to get your waterjet back to cutting precision angles. Did you know that you should always do a ballbar first before calibrating your XD 5 axis head

WATERJET PUMP MAINTENANCE

Have one of our Flow waterjet factory trained technicians inspect and rebuild your pump to get the appropriate lifetime out of it. We work on every model of Flow pump - 40k Cougar, 50k Eagle, 87k Hyperjet intensifier, 60k intensifier, 94i-S, 94i-D, 100i-D, 50i-S, 30sa, 7x, 20x, Hyplex, Hyplex Prime.

REBUILD

We are able to rebuild your waterjet or CNC machine whether that means replacing ballscrews, rails, gear racks, etc. Everything that moves is bound to wear out at some point. Contact us if you have something worn out that needs rebuilt or replaced.

MACHINE LEVELING OR REALIGNING

The ground is constantly moving due to expansion (hot weather) and retracting (cold weather). You should check the level and alignment of your waterjet or CNC machine at least once a year to make sure you are producing precise parts. Schedule one of our factory trained engineers today.

LASER CALIBRATION

To cut precise parts you need a good compensation table to tell your waterjet or CNC machine how far to accurately move. You can achieve this with a laser calibration which can change over time and needs to be performed every time you adjust or change a ballscrew, rack, and pinion.